The Neural Network: A logging tool for now and the future

- Eduardo Alvarez

- Jul 23, 2020

- 3 min read

Authors: Gareth Taylor and Eduardo Alvarez

Cost and safety considerations

Borehole-logging represents a significant proportion of the costs for exploration, appraisal and field development, consequently, wireline and/or LWD logs are often not acquired as operators attempt to keep operational costs in check. Unfortunately, the absence of measured data, especially in the overburden section prevents high-end geophysics and geomechanical analysis from being conducted. These factors result in a limited understanding of the geohazard and geomechanical risk assessment of the overburden.

As machine learning and artificial intelligence capture the audience of the general public, few stop to consider that the greatest solutions are often simple and elegant. In geosciences, there are few solutions quite as elegant as QLog.

The technology has been tried and tested by super majors to small independents in conventional and unconventional settings and can be deployed in look-back mode and in real-time as a well is being drilled. The accuracy of the simulated logs is well within the acceptable range of error expected of repeat runs of a conventional logging tool.

QLog is 60%-80% cheaper than deploying conventional LWD and wireline technology

In addition to the significant cost saving, another significant benefit of deploying QLog relates to the clear HSE benefits afforded by not requiring staff to be on site nor special costly tools or potentially dangerous nuclear sources in the well.

No need for Radioactive tools in the hole

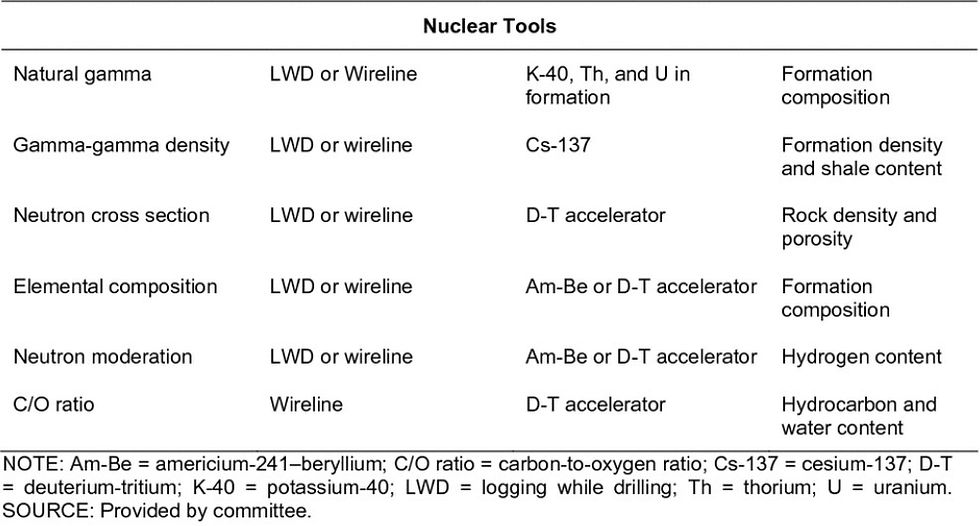

Though HSE protocols for handling radioactive materials are strictly enforced, incidents of lost or misplaced nuclear sources are frequently reported in the oilfield. Figure 2 showcases the various tools that utilize nuclear sources. From this table, it is evident that one of the most crucial formation evaluation logs, formation density, requires nuclear sources to be deployed.

Cs-137 also known as Caesium 137 or radiocaesium is an extremely dangerous substance that is a major bi-product of nuclear reactions. Most famously, Cs-137 continues to be one of the main sources of radiation afflicting the Chernobyl disaster site.

Figure 2 Table of nuclear tools that are use in the well logging process (Source: Committee on Radiation Source Use and Replacement - Nuclear and Radiation Studies Board Division on Earth and Life Studies)

When Quantico developed the QLog technology, one of the main sources of pride around the product was its ability to eliminate the need for dangerous radioactive materials at the wellsite. More recently, QLog was deployed for a client in deep offshore Gulf of Mexico - where it eliminated the need for red-cementing after part of the drill string was lost downhole.

How it works

QLog uses the abundance of drilling data (EDR) acquired by operators to train shallow feed forward neural networks. These networks are trained to map intrinsic physical properties of the drilling process to subsurface rock properties.

Starting with drilling and petrophysical logs from wells in the surrounding area, the Quantico team trains a neural network model to predict rock properties in the area of interest. As the well is drilled, drilling data is used as an input to the neural network. Depending on the model the results can be compressive slowness, shear slowness, bulk density, or neutron porosity.

Figure 3 shows the results of a QLog project in offshore Gulf of Mexico, the accuracy of predictions in this case were 97.6% and 95.2% for RHOB and DTC, respectively.

For this data driven well logging approach, the results are dependent on both the data quality and well control. Given as little as 3 wells for training, QLog can deliver results comparable to repeat runs of a conventional logging tool.

Figure 3 Figure shows the logged density and sonic log in red and the AI predicted log in blue.

Comments